Case Study - KabelSchlepp

Find out how we saved our customer in the insulation manufacturing industry $9,000 through Tsubaki KabelSchlepp...

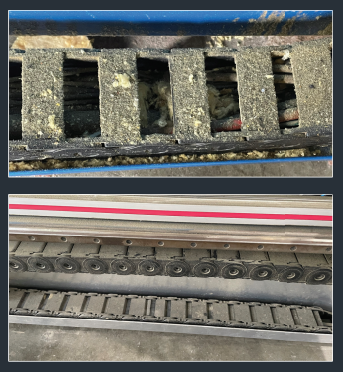

➔Customer Problem

Our customer was experiencing downtime with cable/airline damage from buildup of excess product. Excess insulation material was getting into the energy chain and was causing the chain to bind, break and eventually would damage cables.

Tsubaki offered a solution that included...

- We supplied the energy chain with covers to protect the cables and air hoses and prevent excess insulation material from getting inside the chain.

- Premium top quality product.

➔SAVINGS BREAKDOWN:

- Previous expenses incurred were $5,000 per year in downtime and labour costs.

- Tsubaki solution cost the customer $1,000 and is still running with no downtime and additional labour costs after 2 years.

➔TOTAL CUSTOMER SAVINGS = $9,000 and still running!

Click here to get in touch with a sales representative so we can help your business with the Tsubaki advantage!