Chain Wear Indicator Kit

The Tsubaki Chain Wear Indicator Kits are designed to easily measure roller chain wear elongation, commonly referred to as "stretch." These kits are available for both ANSI and British Standard roller chains.

Detecting and measuring chain wear elongation is critical for achieving reliable operation of industrial chains. Although it is common for users to employ a tape measure or ruler, it is more effective to use a specialized tool to determine whether the chain requires replacement.

Causes of Industrial Roller Chain Wear

Despite common misconceptions, chains do not physically stretch over time when used at rated loads. Roller chain elongation occurs as the material wears away at the chain's pins and bushings, creating more space between these components. This wear can occur due to many factors, such as:

- Insufficient chain lubrication

- Poor maintenance

- High-speed operations

- Frequent heavy loads

- Extreme temperatures

- Exposure to abrasive environments

Measuring Chain Wear

Understanding how to properly measure chain wear elongation will help to proactively ensure optimum performance. When left unchecked, chain wear may eventually result in slippage, poor equipment performance, and unwanted downtime.

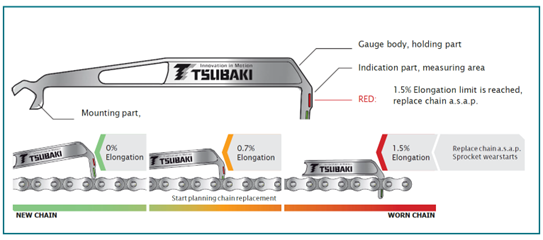

Instead of a ruler or tape measure, experts recommend using a specialized measuring tool that provides a more accurate indicator of chain wear. In order to assure measurement accuracy, the chain should be taut. In most industrial roller chain applications, 1.5%-2% is typically considered wear life limit requiring chain replacement.

Tsubaki's Chain Wear Indicator for ANSI and British Standard

Using our Chain Wear Indicator Tools as part of regular plant maintenance will simplify your chain maintenance operations and keep equipment running optimally.

Chain Wear Indicating Kits Include:

- 5 Chain Wear Measuring Tools

- Chain Wear Indicator Guide

- Roller Diameter Wear Gage

- Width Measuring Tool

Chain Wear Guide Indicator Guide

To get the most out of Tsubaki Chain Wear Indicator Tools, follow these tips:

- Chains do not wear evenly, so measuring the chain in multiple places will ensure the most accurate measurements.

- Check for chain wear during scheduled plant maintenance.

- For optimal chain wear life and maximum uptime, it is recommended to replace chains before reaching 1.5%-2% elongation.

We are pleased to offer our chain wear kits in both ANSI Standard and British Standard measurements.

ANSI Standard

- Part Number ANSICHAINWEARINDIC

- Includes tool sizes 35-80

- Chain wear measurement chart

- Roller diameter wear gauge

British Standard

- Part Number P/N BSCHAINWEARINDICA

- Includes tool sizes 06B-16B

- Chain wear measurement chart

- Roller diameter wear gauge

Instructions for Using Your Tsubaki Chain Wear Indicator Kit

To use the Tsubaki Chain Wear Indicator Kit to its fullest potential, follow these easy steps:

- You will need: Chain Indicator Tool, Chain Wear Indicator Guide, Diameter & Width Measuring Tool.

- Locate the stamp on the outside of the roller chain to determine the roller chain's size.

- Select the indicator tool that is the same size as the roller chain.

- Pull the chain taut.

- Use the Chain Wear Indicator in the kit to determine the degree of elongation by placing the indicator tool's back end around one link and resting it lightly along the taut chain. The indicator will rest between links and show red or green depending on the amount of elongation. Green means no measurable elongation, while red indicates the chain needs replacing.

- Use the Roller Diameter and Roller Link Width Measuring Tools to measure link diameter and width based on the sizes indicated on the front of the tool. Place it over the roller's top to measure the roller diameter and place it inside the roller link to verify that the roller width is still within the desired tolerance.