Home » Australia News » Products » Our customer saved $202,000 by switching to our new Surface-Treated Neptune chain

Our customer saved $202,000 by switching to our new Surface-Treated Neptune chain

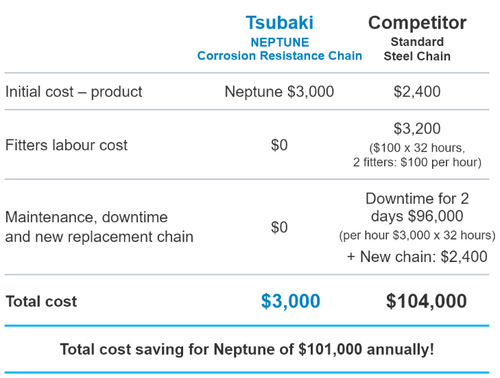

Our customer in the Beverage Industry was using a bottle filling line with standard roller chain to convey bottles at a high speed. The acidic nature of the product and alkalinity of the washdown environment would cause the standard roller chain to rust and elongate. This resulted in lost production and increased maintenance costs.

Our Surface Treated Neptune Chain Solution!

We replaced the customers roller chain with Tsubaki Neptune-Corrosion resistance chain. We installed 80ft of chain and it ran with minimal elongation for over 2 years.

Compared to the previous chain needing to be replaced 4 times over this period, costing our customer time and money.

The customer has not changed their Surface-Treated Neptune chain for over 2 years -- saving a total of $202,000. If they had not switched to Surface-Treated Neptune Chain, the business would have continued losing time and money.

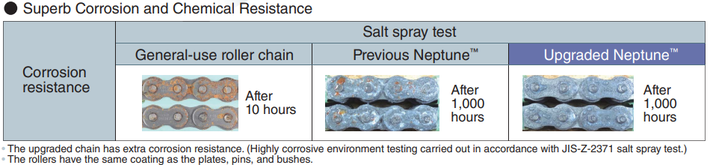

The results speak for itself! See our Salt Spray test below...

Looking for more information? To learn more about how our upgraded Surface-Treated Neptune Chain can help your business thrive, please get in touch with our sales team, here!